Pillatt & Co. Ltd

Pillatt & Co were ironfounders operating, rather incongruously, in the middle of residential housing on Edward Street, Stapleford.

Early days: 1871-1902. The Queen's Road works.

The firm was founded by Andrew Pillatt (1843-1904) who was the son of George Pillatt, a journeyman joiner.[1] In 1861, at the age of 18, he was working as a machine fitter. In 1871 he was an engine fitter and in 1881 he was working as a lace machine fitter. In 1891 he was a foreman in a lace machine builder's works.

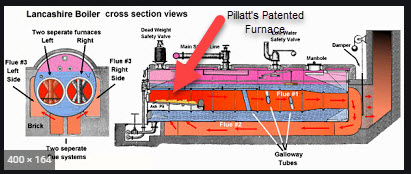

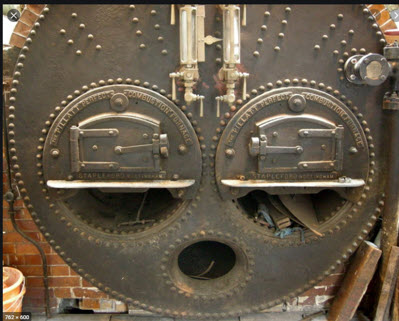

Factory machinery at that time was driven by steam provided by either Cornish-one flue or Lancashire two flues-boilers. The boiler was about 28 feet long and consisted of a flue surrounded by a water jacket. A fire was lit at the end of the flue, in what is called the furnace, and the hot air created then travelled past the water jacket creating steam before exiting via another flue and a chimney. The firebars which formed the base of the furnace, and on which the coal burned, degraded because of the heat and had to be periodically replaced. Andrew's invention was to redesign the fire bars so that they were hollow which enabled them to be cooled, and meant that they lasted longer and the fire burned more efficiently. The furnace itself was also redesigned.

.

Andrew was of modest means and sought a partner with the capital to enable the designs to be patented and developed. In July 1895 Andrew and William Godfrey Gregory, a Nottingham lace manufacturer, filed the first patent for 'Improvements on or relating to firebars.'[2] They entered into a formal partnership on the 6 September 1895 as patent fire bar manufacturers under the id of Godfrey & Pillatt.[3] On the 30 October 1895 he filed, under his own id, a patent for 'Improvement in furnaces or fireboxes for locomotive boilers, traction engines and other purposes, [4] followed by a patent filed in Canada in November 1895.[5] The partnership was terminated on the 28th March 1896[6] and he next entered into partnership with Henry Blagg, John Thorpe Perry, George Anthony Pillatt, William Hall and James Henderson, carrying on business as furnace makers and engineers under the style of A Pillatt & Co, Queens-road works. During this period, he filed a further four patents in Great Britain, one in Canada and four in the Unites States of America. All these were in his own name except for one filed jointly with John Thorpe Perry in August 1896 for improvements in cycle saddles.[7] This agreement was dissolved on the 1 January 1900.[8]

1902: the move to Stapleford

Andrew Ernest Pillatt (1873-1937) was Andrew's eldest son and was apprenticed to his father as a machine builder's apprentice.[9] He became a member of The Institute of Mechanical Engineers graduate section on the 3 Nov 1897, when he was described as assistant works manager at Messrs A Pillatt & Co., Queens Road, Nottingham.[10] After the dissolution of the partnership in 1900 it is probable that Andrew Ernest began to increasingly participate in the running of the undertaking. An agreement was entered into with Walter Wadsworth, a Nottingham lace merchant. The terms of that agreement are not known but in January 1904, when the company Pillatt & Co. was registered[11], he was described as the owner of the business of engineers, iron founders, furnace makers, etc. carried on at Queen's Works, Edward Street, Stapleford, the company having moved there in September 1902.[12] The foundry was built on the site of the old cricket pitch when it was set in the Hall grounds.[13]The first directors were to be his son, John Wadsworth, engineer, who would be chairman, and Andrew Ernest Pillatt. The subscribers were W Wadsworth, lace merchant, J Wadsworth, engineer, T.Galland, chartered accountant, A E Pillatt, Mill House, Stapleford, furnace engineer, J T Perry, solicitor, B A Smith, paper merchant, and J Mallet, traveller & manager. There is no mention of Andrew Pillatt, who was to die in June of that year leaving effects of £6.[14]

Trading history

The records of the company have been deposited with the Manuscripts Dept. of Nottingham University and comprise 37 boxes and 65 volumes. The records date from when the company was formed and there is no earlier material. There are a number of useful series of sales and purchase ledgers but the later years are missing and there is no private ledger to provide an overall view of the company's position. However, an examination of some of the records gives a number of indicators of its progress.

The early years of the company's existence showed sales and work done for the years to 23 January 1905, 1906 and 1907 as £1862, £1,777 and £1,769 respectively.[15] The directors were paid £2 per week and the average wages bill was £12. There was an overdraft of £600 with the Nottingham Joint Stock Bank and debentures with Crompton & Co. A second hand steam engine and boiler was bought for £45 from Herbert Widdowson. In 1905 goods were being sent to the Kanowna gold mine in Australia, although part of the shipment was not paid for.

The second decade of the company saw large exports to Spain China, South Africa and India. The company bought Lancashire or Cornish boilers from the manufacturers in Glasgow and Manchester and fitted them with their patented furnace. The Bought Ledger shows that they typically cost between £500 and £1,000 and would sell for between £1,000 and £1,500 after the new furnaces had been fitted. Typical sales were 6 boilers to Spain in 1919-20 for £8,124[16] (2020 equivalent is £422,293) and 5 boilers to India in 1920 for £5,443.[17] At Christmas 1917 the company purchased 100 cigars from Josiah Brown's in Long Eaton.[18]

John Wadsworth died, aged 45, in August 1919 leaving an estate of £1,572.[19]

.

The company was expanding and land was purchased in 1918 at the side of the works for £74 and at the rear for £147.[20] Further land was purchased in 1918 for £114[21] and in 1918 Frank Martin erected new offices and buildings at a cost of £221.

In the 1920s and 1930s the purchase and sale of large boilers ceased although sets of firebars were sold to be fitted on site. A good example being Papplewick Pumping Station, where three of the boilers have been retrofitted with furnaces supplied by Pillatts. The company's trade report for 1928 describes the merits of their 'Patent Perfect Combustion Furnaces' for all types of boilers. They are either rocking or stationery types and enable small inferior fuels to be used with maximum results. They give big economies in fuel costs and a device completely overcomes smoke nuisance. Air channels keep the bars cool and these give the bars a long life.[22] The original patents had by this time expired but in 1931 they filed a patent for 'the improvement in or relating to incinerators and the like'[23] and the sale of this incinerator, known as the 'PC', became one of their main products.

The company had always supplied the needs of the town and provided many local companies with their engineering requirements. The records are a vignette of local life. Stapleford Brewery, Stapleford Cooperative Society. P Scattergood, gypsum mines, Stapleford Brick, Mansfield Sand, Cossall colliery, F Hooley for carriage, Hooley cycle manufacturer in 1911, Eaton blacksmith 1912, Astra Enamelling Derby Road 1917, purchase of the locomotive 'Llanmorlais' for £400 from David M Davis, Quay Parade, Swansea, in 1918, Staveley Coal & Iron, Mrs. Taylor mangle repairs £1 10s. 6d., Carr Fastener, J Hackett repairs to oven, 11s.9d., W C Hall, tinman, firegrate bottom 2s.9d, oven top 3s.6d., Trowell Mill, Premier Gas Engine, St. Helens, Stapleford in 1922 for stone piers £28 and railings £68, Excelsior Foundry, completion of Edward Street 1929, W Hutchinson, Deacon Garage, cast iron name plate "Mill Road" and fixing 9s.6d. (A E Pillatt lived at the bottom of Mill Road), Stapleford Timber and Joinery, install central heating at the vicarage £90 10s. 0d. etc.

A E Pillatt, described as the managing director of the company, died in March 1937 having collapsed on the platform at Edinburgh while waiting for a train. He was an active worker at St. Helen's church and had held the office of church warden.[24] He left effects of £362.[25]

Closure in August 1958

The company went into voluntary liquidation in August 1958[26] and the liquidator presented his final accounts on the 6 November 1959.[27] The site of the foundry is now occupied by houses.

- Details obtained from family records held in the National Archives

- Pillatt A & Gregory W C (1895) GB189513371A.

- Notts. Archives, M/5077. 6 Sept. 1895.

- Pillatt A (1895) GB189520483A.

- CA51337A

- Notts Archives, M/5078. 28 Mar. 1896.

- Pillat A and Perry J.Y.(1896) GB189618166A.

- London Gazette, 5 Jan. 1900,107.

- TNA, RG12/2705/18.

- Institute of Mechanical Engineers.

- Nottingham Journal, 29 Jan. 1904.

- Notts. Archives, DC/ST/3/1/1

- Stapleford & Sandiacre News, 28 May 1920.

- Grants of Probate 1905.

- Nottm. University, Manuscript & Special Collections, Pi A33,350.

- Nottm. University, Manuscript & Special Collections, Pi A36,50.

- Nottm. University, Manuscript & Special Collections, Pi A36,120.

- Nottm. University, Manuscript & Special Collections, Pi A35,p15

- Grants of Probate 1919.

- Nottm. University, Manuscript & Special Collections, Pi A35, 90.

- Nottm. University, Manuscript & Special Collections, Pi A35, 133.

- Nottingham Journal 1 Jan. 1929.

- Pillatt A E(1931) GB382039A.

- Pillatt A E(1931) GB382039A.

- Grants of Probate 1937.

- London Gazette, 26 August 1958, 5296.

- London Gazette, 6 Oct. 1959, 6303